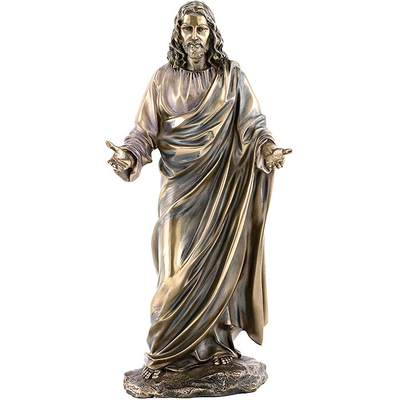

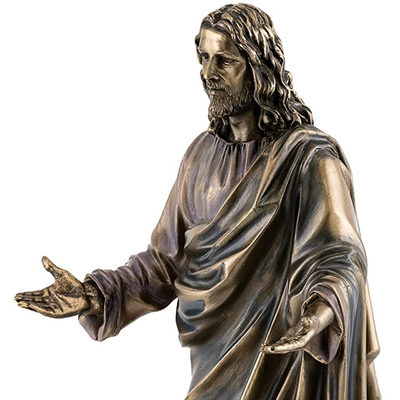

Customized Large Meditating Bronze Jesus Christ Statue Manufacturer for Garden

Bronze is the most popular metal for cast metal sculptures; a cast bronze sculpture is often called simply "a bronze". It can be used for statues, singly or in groups, reliefs, and small statuettes and figurines, as well as bronze elements to be fitted to other objects such as furniture. It is often gilded to give gilt-bronze or ormolu.

| Material |

brass/bronze/copper |

| Color |

Original color/ shinny golden/imitated ancient/green/black |

| Measure |

100-200cm or customize |

Product Range

We can provide bronze busts statue,life size statue,religious sculpture,mary statue,Jesus statue,angel statue,david statue,buddha statue,guanyin statue,animal statue,lion brass statue,lion head statue,horse statue,lion statue,elephant statue,eagle statue,nude lady statue,nude man statue,sexcy statue,garden statue,child kid statue,brass vase,brass column&pillar,outdoor statue,indoor home statue,boy with dog statue,mermaid statue,brass or bronze fountain,lamp statue ,abstract statue,coffe table statue,stainless steel sculpture and so on.

LOST-WAX CASTING: MAKING A BRONZE SCULPTURE IN 12 STEPS

Making the mould – once the sculptor is happy with the design a silicone rubber mould is made of the artwork. This will be the master mould used to originate all castings of the piece of art.

Making the Wax Casting – molten wax is poured into the silicone mould to create a wax duplicate of the artwork

Chasing the Wax – the wax is removed from the silicone mould and any flaws such as air bubbles are addressed by a skilled craftsman

Spruing – once the wax is back to the quality of the original sculpture, it’s time to attach a series of wax rods called sprues. These sprues serve as channels to allow the bronze to flow successfully into all areas of the mould when the final ceramic mould is made. A funnel is also added to allow wax to be lost and for bronze to be poured in.

Investment – it’s now time to create the final mould in which bronze will be poured. This is done by dipping the wax model carefully into investment liquid and then covering it in a fine powder before allowing it to cure (completely dry). This process is repeated using coarse ceramic powder to eventually build up a rigid shell around the wax model.

Burn-Out (Lost Wax) – the shell with its wax inside is now fired in a kiln. At this stage, the wax melts out the pour hole, the funnel added earlier. It is “lost” from the ceramic shell. You are now left with a highly detailed, heavy-duty ceramic mold that is ready to receive the molten bronze.

Casting – once the ceramic mould has been removed from the kiln, molten bronze heated to 1200°C is poured into it and left to cool.

Break Out – once the casting has sufficiently cooled the mould is carefully removed from the bronze model inside. This step can require a significant amount of force as the ceramic mould can be tough and often sledgehammers are needed.

Sandblasting – any remaining fragments of ceramic are removed by blasting fine silicone particles at the model. The sprues which are now cast in bronze are also removed.

Chasing – any weld marks left by assembling sections of a sculpture together are removed and rod marks are chased and re-detailed by hand to match the rest of the bronze surface.

Patination – the bronze is heated and chemical patina is applied by the artist. This is usually a mix of oxides and nitrate and the effect is determined by a number of different factors including heat, saturation of oxides and method of application.

Numbering – the final stage of the process is to number the bronze sculpture according to the casting number and where necessary for limited edition pieces, an edition number.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!